Waterjet cutting services benefits local industries.

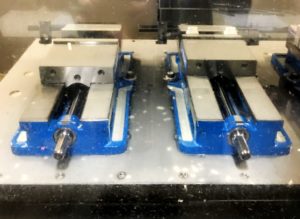

IP Automation provides high pressure water jet cutting service throughout Colorado. With highly adaptable machines, we serve a number of local and national companies.

Our in–house fabrication includes one of Colorado’s largest water jet cutters, featuring a 10×20’ water jet platform. The machinery processes a variety of material densities, from sheets of 1/32″ to 6”.

Fabricating virtually any material: metal, plastic, wood and more!

Thanks to our advanced water jet cutting service, we offer fabrication for virtually any material. We already offer state–of–the–art laser cutting, laser marking and welding for materials such as metals, glass and wood. Now, water jet cutting gives our fabrication services an extra edge.

Water jet cutting systems are ideal for their versatility and precision. Because water jet cutters utilize pressure rather than heat, they leave no heat–affected zone. That’s why water jet cutting is preferred for certain types of materials, such as metals, plastics, textiles and foam.

|

|

Please contact IP Automation today for further information about our water jet cutting service!